Our Process for Packing and Shipping Fire-Resistant Glass

At the heart of our mission to deliver uncompromising safety lies a commitment that begins long before our fire-resistant glass is installed. The final, critical stage of our quality assurance is a meticulous packing and shipping process, designed to guarantee that our high-performance glass arrives at your project site in flawless condition. The accompanying images provide a transparent view of this rigorous procedure.

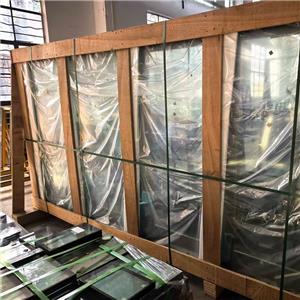

Phase 1: Engineered Packaging in the Warehouse

Our process starts with purpose-built, heavy-duty timber crates, as seen in the bottom image. We do not use standard boxes. Each wooden crate is constructed to the exact specifications of the glass unit it will house. The glass panels, already individually wrapped in a clear, protective plastic film, are carefully placed within a custom interior framework. This design minimizes direct contact, preventing scratches and micro-abrasions that could compromise the glass. The sturdy timber provides a rigid cage that protects against impacts and crushing during handling.

Visible in the image, a bold red-and-white barrier tape with the word "STOP" is prominently applied. This is not merely for show; it is a critical safety and communication protocol. The tape acts as a highly visual warning to all warehouse and logistics personnel, signaling fragile contents that require careful handling. Each completed crate is then mounted on a standard wooden pallet, ensuring seamless and safe movement via forklifts within our facility and onto the transport vehicle.

Phase 2: Secure Loading and Stabilization

The top image captures the next vital step: the careful transfer of these crates onto our dedicated transport. Here, a large, specialized wooden crate containing a major glass unit is being loaded onto one of our delivery trucks. The setting—our factory premises with its industrial background—underscores our controlled, professional environment from start to finish.

A key element of safety is the secure immobilization of the cargo. As shown, our team actively secures the load using heavy-duty ratchet straps with high-visibility, reflective white blocks. These straps are methodically positioned and tightened to distribute pressure evenly and prevent any movement during transit. The worker in the image is ensuring maximum tension, a simple but crucial action that prevents shifting, rubbing, or sudden stress that could lead to damage, regardless of road conditions. The truck itself, represents a link in our trusted logistics chain, chosen for its reliability and suitability for delicate, high-value cargo.

Our Philosophy: Integrity in Every Detail

This two-stage process—engineered wooden crating followed by strategic strapping—embodies our holistic approach. We understand that the integrity of fire-resistant glass is non-negotiable; a single chip or stress point can invalidate its certified performance in a life-threatening situation. Our packaging is therefore an extension of the product itself. The red "STOP" tape, the robust timber, the protective film, and the reflective straps are all part of a system designed to communicate care and enforce caution at every touchpoint.

By investing in such a comprehensive packing and shipping protocol, we fulfill a dual promise: first, to deliver a product in perfect, ready-to-install condition, saving you time and cost from replacements; and second, to uphold the very standard of safety that the fire-resistant glass is meant to provide. When you receive a shipment from us, you receive the assurance that every measure has been taken to protect the component that will, in turn, protect lives and property. This is our standard, visible in every crate we ship and every truck we load.