Key Tools and Equipment for Transporting and Storing Fire-Resistant Glass

Fire-resistant glass is a critical material in modern construction, requiring careful handling during production, transportation, and storage to maintain its structural integrity and performance. This article outlines the essential equipment and tools used in the daily transportation and storage of fire-resistant glass.

1. Transportation Equipment

Forklifts and Pallet Jacks: Heavy-duty forklifts with padded clamps or suction cups are indispensable for moving large glass panels within production facilities. Electric pallet jacks ensure precise positioning during loading and unloading.

A-Frame Glass Racks: These specialized racks secure vertically stacked glass panels during short-distance transfers, minimizing contact and reducing breakage risks.

Air-Ride Suspension Trucks: For long-distance transport, trucks equipped with air-ride systems absorb road vibrations, while climate-controlled trailers prevent thermal stress in temperature-sensitive laminated glass.

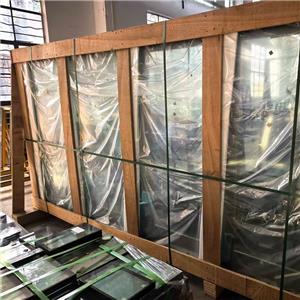

Customized Crates: Reinforced wooden or metal crates with foam padding and corner protectors shield edges from impacts during transit.

2. Storage Solutions

Tilted Glass Storage Racks: Angled racks (5°–10°) allow safe vertical storage, enabling easy access while preventing panels from sliding.

Climate-Controlled Warehouses: Maintaining stable temperature (18–25°C) and humidity (<60%) prevents delamination in multi-layered fire-resistant glass.

Anti-Static Flooring: Conductive epoxy flooring dissipates static electricity, reducing dust adhesion that could compromise fire-resistant coatings.

UV-Blocking Curtains: Protect glass with intumescent interlayers from sunlight degradation in storage areas with skylights.

3. Handling Tools

Suction Cup Lifters: Vacuum-based lifters with rubber seals enable workers to securely grip large panels (up to 1,500 kg capacity) without surface damage.

Edge Protectors: Removable silicone guards prevent chipping during manual handling.

Laser Alignment Systems: Guide precise positioning when stacking panels to avoid uneven pressure points.

Moisture Sensors: Wireless sensors embedded in storage racks monitor humidity levels, triggering alerts if conditions exceed safety thresholds.

4. Safety and Monitoring

RFID Tracking Tags: Embedded tags enable real-time inventory management and traceability throughout the supply chain.

Impact Detection Labels: Smart labels change color upon experiencing excessive G-force, helping identify compromised panels.

Automated Retrieval Systems: Robotic cranes in high-bay warehouses minimize human contact during storage operations.

Conclusion

The transportation and storage of fire-resistant glass demand specialized equipment combining precision engineering and protective features. From vibration-dampened vehicles to intelligent monitoring systems, these tools collectively ensure the material meets rigorous safety standards while optimizing operational efficiency. Continuous advancements in automation and sensor technology are further enhancing reliability in handling this critical construction component.