The Critical Role of Intumescent Seals in Fire-Resistant Glazing Systems

Intumescent glazing seals—often overlooked as mere accessories—are in fact the linchpin of fire-resistant glass systems. These specialized components transform passive glazing into active fire barriers by expanding up to 10× their original volume when exposed to heat, sealing critical gaps between glass edges and framing. This dynamic response is fundamental to containing flames, smoke, and toxic gases during building fires. Here, we examine their engineering principles, performance standards, and transformative impact on fire safety.

? The Science Behind Intumescent Seals

Intumescent seals are typically composed of hydrated sodium silicates, graphite, or polymer-based compounds. When temperatures reach 110–120°C, these materials undergo a chemical reaction:

Dehydration: Releases water vapor, cooling adjacent surfaces and delaying heat transfer

Expansion: Forms a rigid, insulating char foam (up to 5 cm thick) that fills gaps between glass and frames

Insulation: The char layer reduces thermal conductivity to ≤0.15 W/(m·K), preventing frame ignition and maintaining glass integrity

Without these seals, even fire-rated glass fails prematurely. Gaps as small as 1 mm can allow 1,200°C flames to penetrate within 10 minutes, compromising escape routes

?️ Performance Standards and Testing

Intumescent seals must meet rigorous criteria to certify fire-resistant glazing systems:

Integrity (E-class): Prevents flame/smoke passage for 30–120 minutes (e.g., BS 476-22, GB 15763.1)

Insulation (EI-class): Limits temperature rise on the non-fire side to ≤140°C average, ≤180°C peak

Hose Stream Test: Validates structural stability after fire exposure by resisting high-pressure water jets

Seals like Intumastic acrylic firestop undergo 3-hour system tests, expanding to seal irregular penetrations (cables, pipes) while maintaining flexibility for seismic movement

⚙️ Strategic Applications in Fire-Resistant Glazing

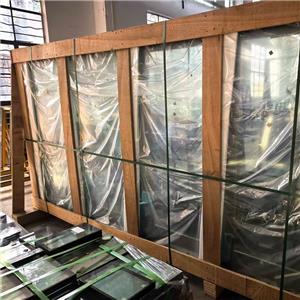

1. Perimeter Sealing in Framing Systems

Timber/Metal Frames: Intumescent gaskets compress glass edges, accommodating thermal expansion. During fires, they expand asymmetrically to counteract frame warping, maintaining seal integrity

Curtain Walls: Hybrid seals with graphite cores block radiant heat transfer at spandrels, preventing fire leapfrog

2. Joint and Penetration Sealing

Cable/Wall Openings: Intumescent pillows (e.g., fireproof sponge + silicate) plug voids around pipes or conduits. Unlike mortar, they allow retrofitting without demolition

Movement Joints: Water-based acrylic sealants (e.g., Topsen’s red-colored variant) permit ±25% joint movement while providing 3-hour fire resistance

3. Fire-Rated Doors and Partitions

Glass Doors: Edge seals in fire doors with ceramic glass (e.g., PYROBEL) expand to stabilize glass under thermal stress, preventing fallout

Glass Partitions: In non-insulating E-class glazing, seals compensate for glass edge degradation, extending integrity by ≥30 minutes

? Installation and Maintenance Imperatives

Precision installation is non-negotiable:

Edge Protection: Seals must fully contact glass edges protected by aluminum foil to prevent silicate gel degradation from UV or humidity

Frame Compatibility: Steel frames require ceramic fiber pads to mitigate heat conductivity; timber needs char-resistant coatings

Quality Control: Gaps >3 mm or adhesive failures reduce fire resistance by ≥50%

Maintenance protocols include:

Annual smoke penetration tests (per ASTM E283) to detect seal compression fatigue

Replacement if seals exhibit cracking, shrinkage, or UV damage.

? Conclusion: Beyond Compliance to Life Safety

Intumescent seals exemplify engineered adaptability—transforming vulnerabilities (gaps) into robust fire defenses. By sealing the weakest links in glazing systems, they enable fire-resistant glass to fulfill its life-saving mandate: containing fires for 30–120 minutes, facilitating evacuation, and protecting structural integrity. As high-rise construction embraces larger glazed areas, innovations like nanosilicate-enhanced seals (with 20% faster activation) will further integrate fire safety with architectural transparency.