Choosing the Right Fire-Rated Glass for Chemical Laboratories

Chemical laboratories present unique fire safety challenges due to the presence of flammable substances, high-temperature processes, and corrosive chemicals. Selecting the appropriate fire-rated glass is critical to ensuring personnel safety, protecting equipment, and complying with international building codes. As a leading fire-rated glass manufacturer based in Zhongshan, Guangdong, we specialize in engineering solutions tailored to the demanding environments of modern laboratories. This article explores key considerations for choosing fire-resistant glass in chemical labs and highlights advanced technologies that set global standards.

1. Unique Fire Risks in Chemical Laboratories

Chemical labs operate under conditions that amplify fire hazards:

Flammable Liquids/Gases: Solvents, fuels, and compressed gases can ignite rapidly.

Exothermic Reactions: Uncontrolled reactions may generate intense heat (>1,000°C).

Corrosive Exposure: Acidic or alkaline vapors degrade conventional materials.

Structural Stress: Thermal shocks from explosions or quenching procedures.

Traditional fire-rated glass often fails in such scenarios due to insufficient thermal resistance, poor chemical stability, or lack of structural integrity.

2. Critical Performance Criteria for Lab Fire-Rated Glass

A. Fire Resistance Duration

Laboratories require extended fire protection to allow safe evacuation and containment.

Minimum Rating: 60–120 minutes (tested per ASTM E119/EN 1364-1).

Advanced Option: Ceramic-based glass withstands 180+ minutes at 1,200°C.

B. Thermal Shock Resistance

Sudden temperature changes (e.g., from liquid nitrogen spills to Bunsen burner flames) demand glass with low thermal expansion coefficients.

Borosilicate Fire Glass: Retains integrity at -50°C to 450°C (ΔT >500°C).

C. Chemical Corrosion Resistance

Hydrofluoric acid, chlorine, and organic solvents require specialized coatings or laminated interlayers.

PVB-Free Interlayers: Silicone-based layers resist swelling/delamination under chemical exposure.

Acid-Etched Surfaces: Reduce reactivity with corrosive vapors (tested per ISO 17526).

D. Impact and Blast Resistance

Explosion-proof designs integrate tempered glass layers and reinforced framing.

Multilayer Laminated Glass: Withstands 300 kPa blast pressure (EN 13541).

E. Optical Clarity and UV Stability

Maintain visibility for safety monitoring without yellowing over time.

Low-Iron Glass: 92% light transmission even after prolonged UV exposure.

3. Recommended Fire-Rated Glass Types for Labs

Type 1: Hybrid Ceramic-Composite Glass

Structure: Ceramic interlayer + tempered glass + intumescent sealant.

Advantages:

180-minute fire rating.

Resists HF acid (up to 48 hours at 20% concentration).

Anti-fogging properties for emergency visibility.

Applications: Fume hood windows, lab partition walls.

Type 2: Borosilicate Fire Glass with Silicone Edge Seals

Structure: 3-layer borosilicate panels + high-temperature silicone gaskets.

Advantages:

Operates from -196°C (cryogenic) to 800°C.

Zero deformation under thermal cycling.

Applications: Glove box windows, reactor observation panels.

Type 3: Wire-Reinforced Laminated Glass

Structure: Wired mesh embedded within 2–3 glass plies.

Advantages:

Prevents glass collapse post-fire exposure.

Meets OSHA’s “Safe Breakage” requirements.

Applications: Emergency exit doors, explosion-prone zones.

4. Compliance with Global Standards

To access overseas markets, ensure glass meets regional certifications:

North America: NFPA 257, UL 9.

EU: EN 1363-1, CE Marking.

Middle East: Civil Defense Code (e.g., UAE CFR 2018).

Asia-Pacific: AS 1530.4 (Australia), GB 15763.1 (China).

As a Zhongshan-based manufacturer, our products hold dual certifications (e.g., UL + CE), streamlining compliance for international clients.

5. Cost vs. Lifetime Value Analysis

While advanced fire-rated glass costs 20–40% more than standard types, labs benefit from:

Reduced Insurance Premiums: Up to 15% discounts for compliant installations.

Lower Replacement Costs: 10+ year lifespan vs. 3–5 years for uncoated glass.

Operational Continuity: Avoid $250k+ losses from lab shutdowns (per fire incident study by FM Global).

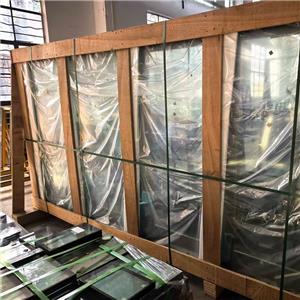

6. Partnering with a Certified Manufacturer

When sourcing fire-rated glass, prioritize suppliers who:

Offer Custom Engineering: Tailor thickness, coatings, and framing to lab layouts.

Provide Third-Party Test Reports: Validated by SGS, TÜV, or Intertek.

Support Installation: Collaborate with architects to ensure airtight fire seals.