For When Your Design Isn‘t a Simple Rectangle

For When Your Design Isn‘t a Simple Rectangle

The Power of Custom-Shaped Fire Glass

Modern architecture often shuns the mundane right angle in favor of dynamic curves, sharp angles, and irregular geometries that create stunning visual impact. However, for decades, incorporating fire safety into these innovative designs meant compromising the vision, often by breaking up curved walls with obstructive rectangular frames or abandoning glass altogether in favor of conventional materials. This era of compromise is over. The advent of custom-shaped fire-resistant glass has fundamentally changed the relationship between safety and design. Specialized manufacturers like PYRONANO utilize advanced manufacturing techniques to produce fire-rated glass in a vast array of shapes—including gentle curves, acute triangles, trapezoids, and complex polygons. This capability allows architects to specify large-scale, curved fire-resistant glass walls that flow with the building's form, or angled fire-rated partitions that create unique spatial experiences, all without sacrificing the critical EI60 or EI120 fire protection ratings. This is not merely a product offering; it is a tool for realizing bold architectural concepts that were once deemed impractical or unsafe.

Precision and Performance in Complex Forms

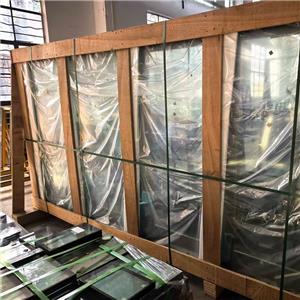

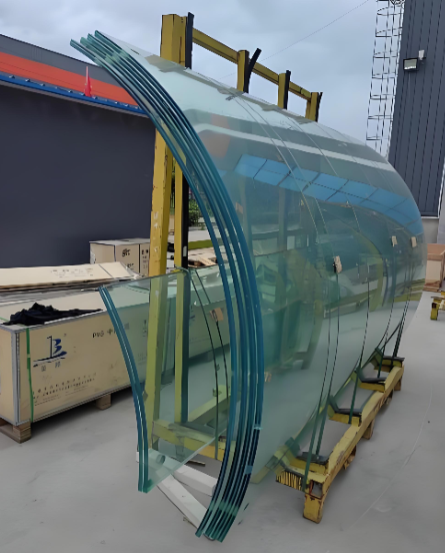

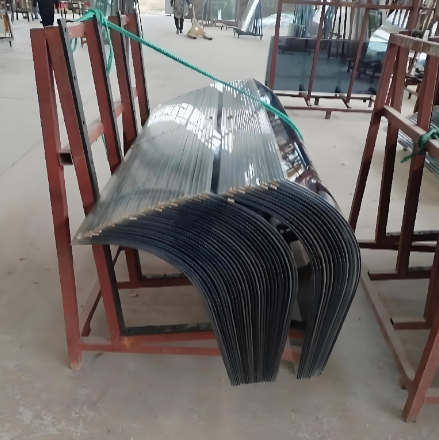

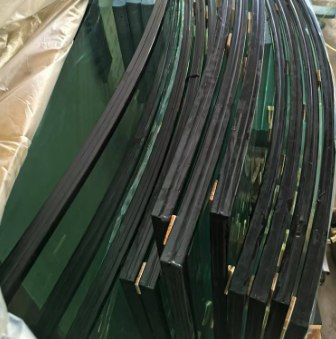

Creating a fire-resistant glass panel in a non-standard shape is far more complex than simply cutting a piece of glass to a pattern. The fire-resistance performance is intrinsically linked to the integrity of the entire laminated assembly. For curved glass, the challenge lies in the precise heat-soak tempered bending process. Each layer of glass must be curved to an exact radius, and the critical fire-resistant interlayer must be perfectly bonded throughout the curvature without any air pockets or delamination points that could become failure points under intense heat. For polygonal shapes with sharp angles, the focus shifts to the precision edge work and sealing. The edges must be cut and polished to perfection, and the integrity of the seal around the entire perimeter is paramount to prevent the penetration of flames and hot gases. This requires not only state-of-the-art machinery but also rigorous quality control at every stage. Each custom piece is part of a larger certified glazing system, ensuring that even the most unconventional shape performs predictably and reliably when it matters most.

From Single Panel to Complete Vision

The ultimate test of custom-shaped fire glass is its ability to integrate seamlessly into the overall architectural design, functioning as both a stunning aesthetic element and a robust safety component. This involves meticulous attention to system integration details. For instance, in a frameless curved glass wall using butt-joint technology, the supporting structure must be engineered to match the precise curvature, and the joint details must maintain their integrity under fire conditions. The goal is to create a harmonious whole where the fire protection is invisible, allowing the design to take center stage. This capability opens up transformative applications: curved fire-rated stairwells that become architectural centerpieces, triangular fire-resistant windows that accentuate a roofline, or zigzagging partitions that define space in an art gallery. By solving the technical challenges of shape, specialists like PYRONANO empower architects to use fire-rated glass not as a limitation, but as a primary medium for artistic and functional expression, ensuring that the most ambitious designs are also the safest.

The ability to specify fire-resistant glass in any shape marks a pivotal advancement in architectural design. It dissolves the last remaining barrier between uncompromised safety and boundless creativity. No longer must form follow a simplistic function. Now, for curved atriums, angled corridors, and polygonal facades, the function of fire protection can follow the most expressive of forms. This ensures that the buildings of the future will be as safe as they are spectacular, proving that with the right technology, there is no longer a need to choose between a visionary design and a protected one.