The Role of Laminated Layers in Fire-Resistant Glass

The Role of Laminated Layers in Fire-Resistant Glass

The Composite Nature of Modern Fire Protection

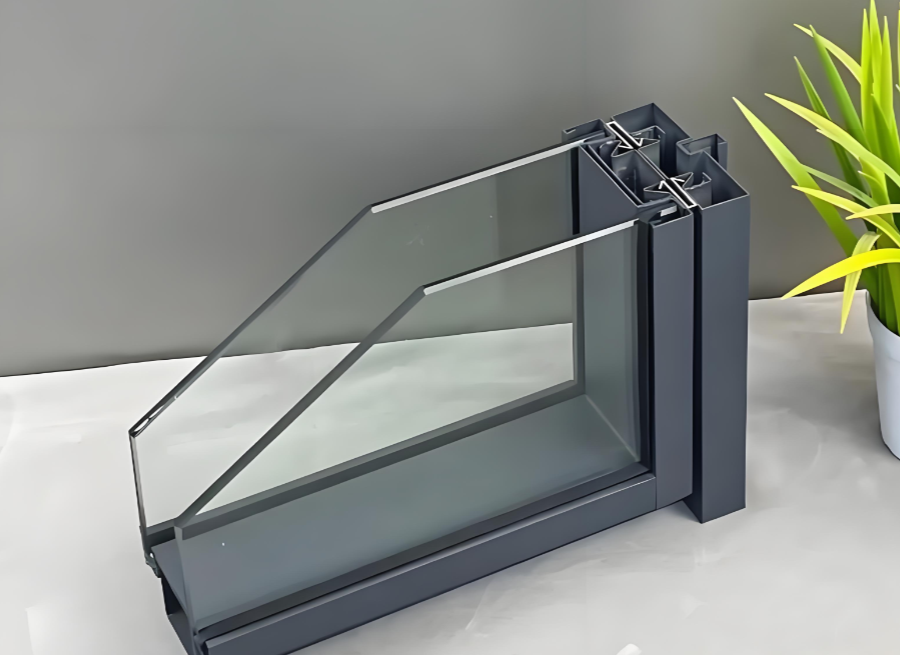

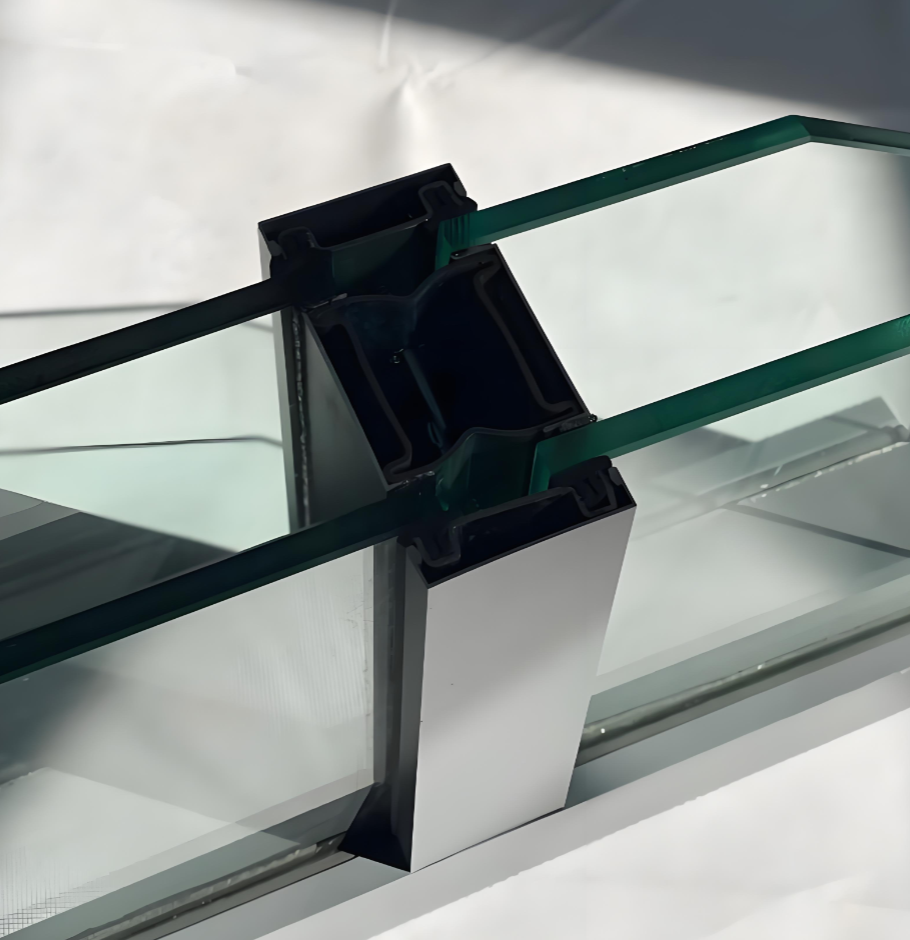

The fundamental difference between ordinary glass and high-performance fire-resistant glass lies not in a single magical ingredient, but in a sophisticated composite structure. While standard annealed or tempered glass may shatter almost immediately upon exposure to fire, modern fire-rated glazing is engineered to remain intact and provide a barrier for a specified duration (e.g., 30, 60, or 120 minutes). This performance is achieved primarily through laminated layers. At its core, fire-resistant glass is a laminated assembly, typically consisting of two or more sheets of glass bonded together by one or more transparent interlayers. This construction is a critical departure from monolithic glass. The laminated layers work in a synergistic manner: the glass panes provide initial structural strength and rigidity, while the interlayers are the key to the fire-resistant properties. PYRONANO’s technical specifications, which detail complex structures like 5G+5F+5G+5F+5G(for a 25mm EI60 product), clearly illustrate this multi-layered approach. Each component—the glass (G) and the special interlayer (F)—has a distinct and vital role to play in the overall performance of the assembly, transforming a brittle material into a resilient, life-saving barrier.

The Active Fire-Fighting Core

The most critical component within the laminated layers of integrity and insulation class (EI) glass is the intumescent interlayer. This is not a simple polyvinyl butyral (PVB) interlayer used in standard laminated safety glass. Instead, it is a specially formulated, transparent material that remains stable under normal conditions. However, when exposed to the intense heat of a fire, this interlayer undergoes a dramatic chemical transformation. It expands (intumesces), turning from a clear film into an opaque, thick, and foamy insulating char. This expansion is the cornerstone of the glass's ability to provide insulation (I). The expanded char acts as a highly effective heat shield, significantly reducing the temperature on the unexposed (safe) side of the glass. This process is what allows PYRONANO’s EI60 and EI120 glass to limit heat transfer, preventing the ignition of combustible materials on the protected side and ensuring that the surface remains safe to touch, which is crucial for safe evacuation routes. The sequence and thickness of these intumescent interlayers within the laminate are precisely engineered to provide protection for the required fire resistance period.

Achieving Integrity, Strength and Safety

The role of the laminated layers extends beyond just housing the intumescent interlayer; they create a system where the whole is greater than the sum of its parts. The multiple glass panes within the laminate contribute significantly to the integrity (E) of the assembly. Even if one pane cracks due to thermal stress, the other panes and the interlayer hold it in place, preventing the formation of an opening that would allow flames and hot gases to pass through. Furthermore, the lamination process itself creates a safety glass product. In the event of impact, the glass fragments adhere to the interlayer, preventing dangerous shards from causing injury—a key safety feature in public areas. The specific configuration of the laminated layers, as seen in PYRONANO’s diverse product range, is tailored to meet different performance criteria. A structure with more glass and interlayer pairs (e.g., for EI120) is designed to withstand longer fire exposure. This sophisticated, system-based approach to glass lamination is what enables PYRONANO to create reliable, certified fire-resistant glazing that meets the stringent demands of modern architecture and life safety codes.

The laminated layers are the unsung heroes of fire-resistant glass, transforming a basic material into an intelligent, reactive life-safety system. The strategic combination of glass panes and specialty interlayers, particularly the intumescent interlayer, is what enables modern fire-rated glazing to provide critical protection against flames, smoke, and heat. PYRONANO’s expertise in engineering these complex laminated assemblies ensures that transparency in architecture no longer comes at the expense of safety, but is fundamentally integrated with it through advanced material science.