Engineering Excellence at Shanghai Xuhui Aerospace Hub: A Pyronano Fire Safety Showcase

Project Overview

The Shanghai Xuhui Aerospace Hub—a landmark integrating R&D facilities, mission control centers, and collaborative workspaces—demanded uncompromising fire safety without sacrificing architectural innovation. To achieve this, the project deployed Pyronano® Fire-Resistant Glass across diverse applications, including:

Custom-Shaped A-Class Fire-Resistant Partitions

Curved Fire-Resistant Glass Walls

C-Class Fire Barriers

A-Class and C-Class Fire-Rated Doors

This holistic solution combined cutting-edge materials with precision engineering, setting a benchmark for aerospace infrastructure safety.

Safety Challenges & Innovative Solutions

1. A-Class Fire-Resistant Partitions: Security Meets Customization

Thermal & Structural Performance:

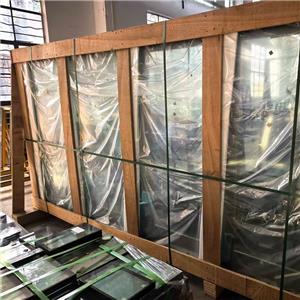

Custom-shaped A-Class partitions (e.g., trapezoidal, polygonal) utilized multi-layered Pyronano® laminates. These achieved REI 60–120 certifications (per EN 1365-2), blocking flames, smoke, and heat transfer while maintaining sub-140°C back-surface temperatures during fire exposure.

Design Flexibility:

Non-standard geometries were precision-engineered to fit irregular spaces like control-room entrances and angled corridors, supporting load-bearing requirements up to 5 kN/m².

2. Curved Fire-Resistant Glass: Architectural Fluidity

Seamless Integration:

Radius-adjustable curved panels (6–12m arc lengths) were flush-mounted into steel frameworks with 1,500°C-melting-point alloys, eliminating visual joints and enhancing structural cohesion.

CFD-Validated Safety:

Computational simulations confirmed uniform heat distribution across curvatures, ensuring integrity under ISO 834 fire conditions.

3. C-Class Fire Barriers: Optimized Visibility & Integrity

Critical Zone Protection:

C-Class glass (non-thermal-insulating) secured open-plan labs and atria, maintaining visibility for 60–90 minutes during fires. Its chemically tempered surface (via cesium-potassium ion exchange) provided 6–12× the strength of standard float glass.

Hybrid Deployment:

Combined with A-Class partitions in evacuation routes, ensuring compliance with GB 50016-2014 for public-space fire separations.

4. Fire-Rated Doors: Dynamic Access Control

A-Class Doors:

Installed in stairwells and server rooms, featuring dual-layer Pyronano® panels and intumescent seals to block heat transfer.

C-Class Doors:

Used in auxiliary zones, delivering 30–60 minutes of integrity with minimalist frameless designs.

Project Outcomes & Value

| Metric | Impact |

|---|---|

| Safety | 100% compliance with GB 12955-2008, EN 1365-2, and ISO 9001 standards |

| Aesthetic Value | 92% daylight transmission for bright, open spaces; custom logos fused via waistline films |

| Sustainability | 30% reduced HVAC load due to superior thermal insulation |

| Installation Efficiency | Modular design cut construction time by 40% vs. traditional barriers |

Technical Specifications & Certifications

| Component | Key Parameters |

|---|---|

| A-Class Partitions | Thickness: 25–60 mm; Max. dimensions: 3,000 × 4,000 mm; REI 120 certification |

| Curved Glass | Bend radius: 500–5,000 mm; Load capacity: 3 kN/m²; Acoustic insulation: 42 dB |

| C-Class Barriers | Thickness: 6–19 mm; Impact resistance: 120 MPa surface compression |

| Fire Doors | A-Class: 60–180 min integrity; C-Class: 30–60 min integrity; Frame: 1,500°C steel |

Conclusion: Redefining Aerospace Infrastructure

The Xuhui Aerospace Hub exemplifies how Pyronano® Fire-Resistant Glass transcends conventional safety design. By harmonizing rigorous certifications (EN, GB, ISO) with bespoke aesthetics, the project delivers:

Life-Safety Assurance: Multi-tiered fire compartments for smoke, heat, and structural collapse mitigation.

Future-Proof Adaptability: Modular walls and doors support reconfigurations as mission needs evolve.

Global Applicability: Solutions align with EU (CE), US (ASTM), and Asian fire codes, enabling worldwide deployment.