How to provide customized size fireproof glass

How to provide customized size fireproof glass

Initial Consultation and Technical Requirement Analysis

The journey to providing customized fireproof glass begins with a deep-dive consultation to fully understand the project's specific requirements. This initial phase is critical and involves gathering key parameters such as the exact dimensions (height, width, and thickness), the required fire resistance rating (e.g., EI30, EI60, EI120), and the intended application (e.g., door, partition, curtain wall, or walkable floor). PYRONANO's technical team works closely with architects, contractors, and clients to analyze the architectural drawings and the fire safety regulations applicable to the project's location. This collaborative approach ensures that the proposed custom glass solution not only fits the physical opening but also complies with local building codes, whether they follow BS EN, ASTM, or other international standards. The goal is to define a clear and technically sound specification from the outset.

Engineering, Manufacturing, and Quality Assurance

Once the specifications are finalized, the engineering and manufacturing phase commences. For custom sizes, especially oversized or non-standard shapes, this involves sophisticated engineering calculations to ensure the glass assembly will maintain its structural integrity and fire resistance under stress. PYRONANO leverages its German core technology to produce complex laminated structures. The process involves cutting high-quality glass to the precise dimensions, followed by meticulous cleaning, assembly with transparent intumescent interlayers (and acoustic PVB if required), and autoclaving to create a flawless bond. For projects requiring extreme sizes, such as panels over 5 meters tall, the company's expertise in handling large-scale laminates and its in-house testing capabilities are brought to bear. Each custom piece undergoes rigorous quality checks to verify that it meets the predefined performance criteria before it moves to the packing stage.

Secure Packing, Logistics, and On-Site Support

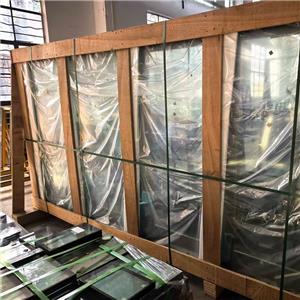

The final, crucial step is ensuring the custom-sized fireproof glass arrives at the project site in perfect condition. PYRONANO has developed a specialized packing and shipping process for fire-resistant glass. Custom-sized crates or A-frame packaging with reinforced edges and shock-absorbent materials are used to protect the glass from transit vibrations, impacts, and environmental factors. Each piece is clearly labeled with identification information and handling instructions. The company coordinates with reliable logistics partners to manage transportation, providing tracking information and ensuring timely delivery. Furthermore, PYRONANO's support extends to the site with detailed installation guidelines and accessible technical support to assist with any queries during the installation process, ensuring a seamless integration of the custom product into the building.

In summary, providing customized size fireproof glass is a comprehensive, collaborative process that PYRONANO has mastered. It spans from initial technical consultation and precise engineering to secure logistics and ongoing support. This end-to-end service guarantees that clients receive a perfectly fitted, high-performance fire safety solution that meets the exact demands of their unique architectural vision, backed by rigorous quality assurance and expert guidance.