Butt Joint Technology in Frameless Fire Glass Systems

Butt Joint Technology in Frameless Fire Glass Systems

The Pursuit of Seamless Transparency

In modern architecture, the demand for maximum transparency and clean lines has driven the evolution of fire safety solutions. Butt joint technology represents a revolutionary advancement in frameless fire glass systems, eliminating the need for bulky, visible vertical frames between glass panels. Instead of being held within a perimeter of metal, the glass panels are precision-engineered to meet edge-to-edge, creating a near-invisible joint that preserves the aesthetic integrity of large glazed areas. This approach allows architects to design stunning, uninterrupted fire-rated barriers—such as walls, partitions, and screens—that fulfill stringent safety codes without compromising the minimalist vision. PYRONANO's expertise in this domain is demonstrated by their development of systems tested for impressive heights, such as 5-meter panels, validated by independent bodies like Efectis Holland, proving that safety and sophistication can coexist seamlessly.

How Butt Joints Maintain Fire Integrity

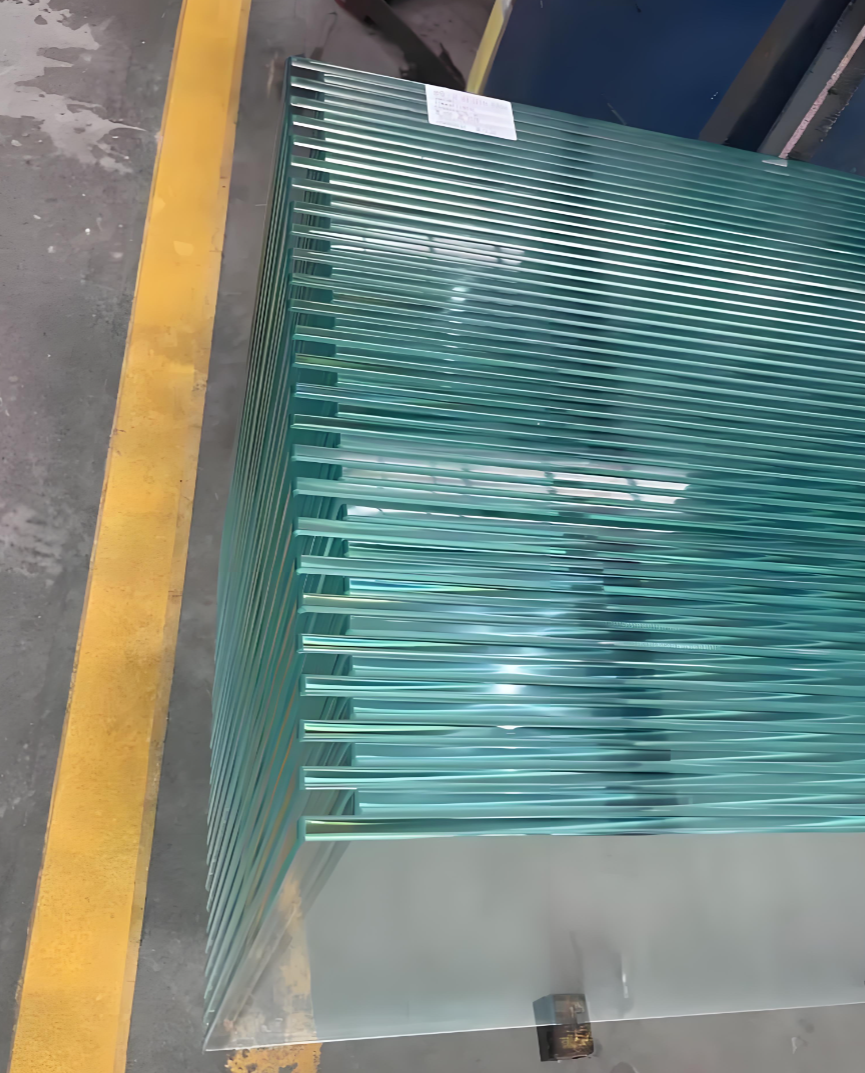

The core challenge of butt joint technology is ensuring that the narrow gap between panels does not become a weak link during a fire. This is achieved through a combination of precision engineering and high-performance materials. The glass panels used are typically thick, multi-layer laminates with intumescent interlayers. Specially designed, minimal-profile vertical clamp fittings hold the panels in place at the top and bottom, allowing the vertical edges to remain free. Critically, a proprietary fire-resistant sealant or an intumescent gasket is applied within the joint. Upon exposure to heat, this material expands rapidly, sealing the gap completely and preventing the passage of flames, hot gases, and smoke. PYRONANO's German core technology ensures that this system is meticulously calculated and tested to maintain the Integrity (E) and Insulation (I) criteria for the required duration, such as EI60 or EI120, making the joint as fire-resistant as the glass itself.

Applications and Advantages Beyond Aesthetics

The benefits of butt joint systems extend beyond their visual appeal to encompass practical and performance advantages. By removing obstructive vertical frames, these systems enhance the flow of natural light and create a more open, spacious environment. They are ideally suited for high-end commercial lobbies, corporate offices, retail spaces, and any application where an unobstructed view is paramount. Furthermore, the technology allows for greater design flexibility, enabling the creation of curved fire-resistant glass walls by connecting straight panels at angles. For manufacturers like PYRONANO, offering this technology signifies a commitment to innovation, allowing them to provide clients with state-of-the-art solutions that meet the highest standards of both safety and contemporary design. The successful implementation of these systems requires precise measurement, expert installation, and trusted product performance, areas where PYRONANO's project support excels.

In conclusion, butt joint technology is a cornerstone of modern frameless fire glass systems, successfully marrying impeccable aesthetics with robust fire engineering. It transforms fire barriers from functional necessities into design features, enabling the creation of safe, transparent, and architecturally stunning spaces. PYRONANO's leadership in developing and certifying these systems underscores their role as a forward-thinking specialist, providing clients with cutting-edge solutions where the line between safety and art gracefully disappears.