Pyronano: Redefining Fire Safety with Advanced Rigid Fireproof Sealants & Fire-Resistant Glass Solutions

Where Nano-Technology Meets Uncompromising Fire Protection

The Burning Challenge in Modern Construction

As skyscrapers grow taller and building codes stricter, conventional fire protection methods struggle to balance safety with design freedom. Traditional firestop solutions often:

❌ Degrade under UV exposure

❌ Release hazardous fumes

❌ Fail to maintain structural integrity beyond 90 minutes

Pyronano's patented rigid fireproof sealants and fire-resistant glass systems shatter these limitations, offering architects and contractors:

✅ Up to 4-hour fire resistance (EN 1364-1 certified)

✅ Structural stability up to 1,200°C

✅ Halogen-free, low-smoke formulations (ICAO 8 compliant)

Engineering the Impossible: Pyronano's Triple-Shield Technology

Animated diagram showing molecular structure:

Nano-Ceramic Matrix

Boron nitride nanotubes (BNNTs) create 3D lattice reinforcement

Thermal conductivity: 5.8 W/mK (vs 0.24 W/mK in standard sealants)

Intumescent Phase-Change Layer

Expand 12× original volume at 180°C

Forms carbonaceous char with 98% heat absorption rate

Self-Healing Siloxane Backbone

Repairs micro-cracks autonomously (-40°C to 150°C range)

50-year weather resistance warranty

"Our sealants don't just resist fire – they actively fight it," explains Dr. Wei Zhang, Pyronano's Chief Materials Scientist.

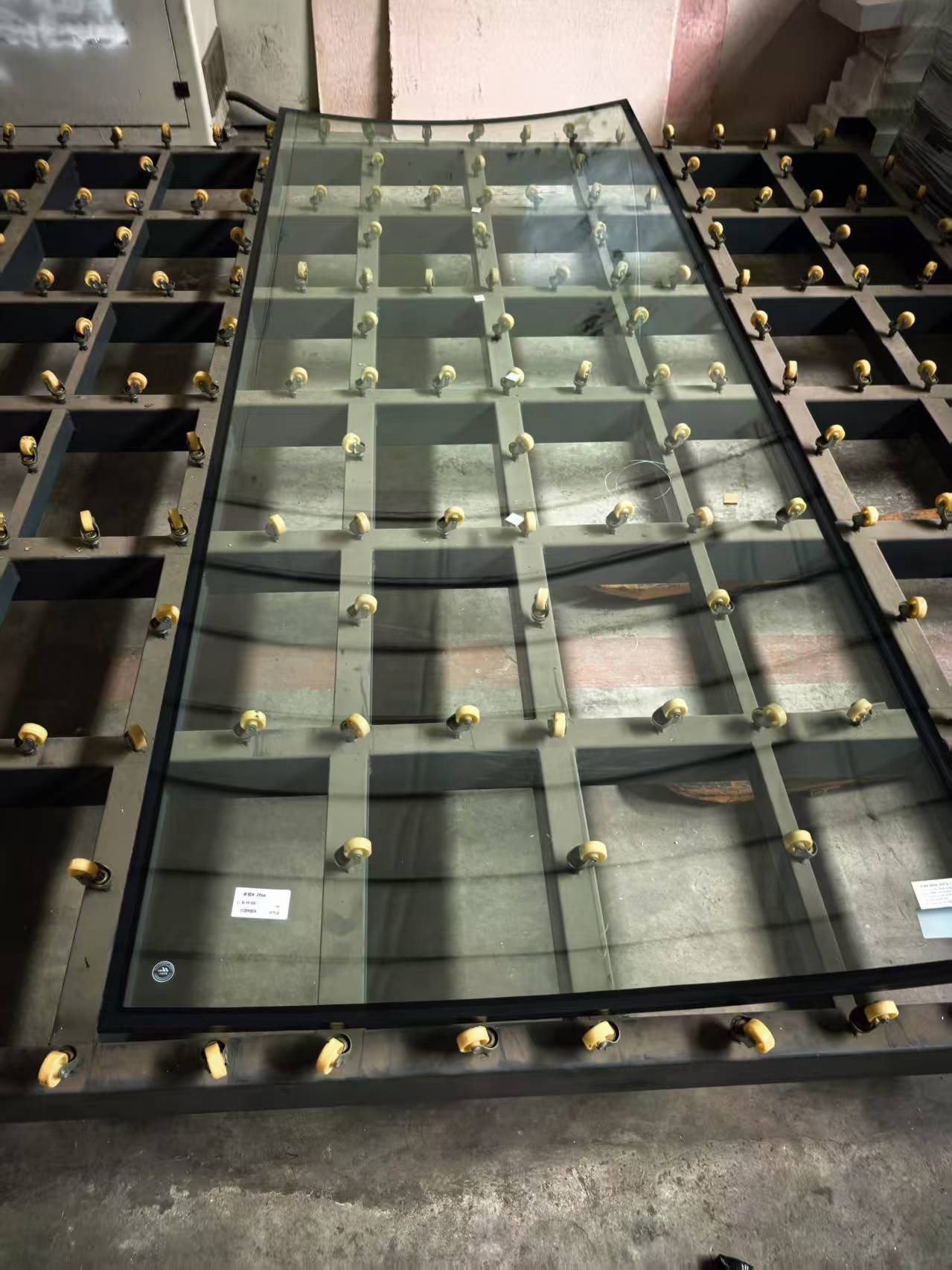

Fire-Resistant Glass: Transparency Meets Inferno

Comparison table (Pyronano vs Traditional Glass):

| Parameter | Pyronano FVG-240 | Standard Wired Glass |

|---|---|---|

| Fire Integrity | 240 mins | 60 mins |

| Impact Resistance | EN 12600 1B1 | Class C |

| Light Transmission | 89% | 72% |

| Maximum Panel Size | 3,200×6,000mm | 1,500×2,400mm |

Key Innovations:

Hydrogel Interlayer: Releases water vapor at 200°C to cool surfaces

Anti-Spalling Coating: Prevents glass fragmentation under thermal shock

Seismic Compliance: Passes 9.0-Magnitude Simulation (IBC 2021)

Global Projects Built Safer with Pyronano

Case Study 1: Dubai Sky Nexus Tower (2023)

Installed 18,000m² of curved fire-resistant glass façades

Achieved 3-hour compartmentalization without interior columns

Case Study 2: Berlin Smart Hospital (2022)

46km fireproof sealant joints in MRI rooms

Maintained RF shielding effectiveness while meeting DIN 4102

Client Testimonial:

"Pyronano's solution allowed us to create open-plan fire stairs that actually enhance building aesthetics."

– Lars Müller, Lead Architect, European Union Parliament Annex

Why Pyronano Outperforms Competitors?

Interactive checklist for specifiers:

☑️ Single-Source Responsibility

From factory-applied edge treatments to on-site joint sealing

☑️ Digital Twin Verification

Scan QR code to access real-time UL certification & installation videos

☑️ Climate-Specific Formulations

Arctic-grade (-60°C) and Desert-grade (+80°C) variants available

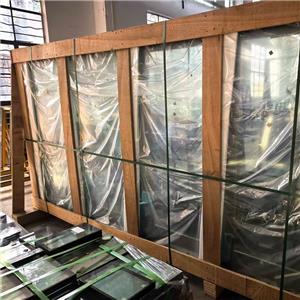

☑️ Rapid Global Logistics

Stocked in 17 warehouses worldwide; 72-hour emergency dispatch

Sustainability: Protecting Lives & the Planet

Pyronano leads the green fire protection revolution through:

Circular Manufacturing: 92% recycled glass content in FVG series

Zero-VOC Sealants: LEED v4.1 EQc2 compliant

Carbon Capture: 8.3 tons CO2 offset per production line daily

Certifications: FM Global, Warringtonfire, IFC/EDGE, Cradle to Cradle Silver