Manufacturing Process of Rigid Fire-Resistant Glass with Hollow Interlayer: Filling and Curing Techniques

Rigid fire-resistant glass, a critical component in modern fire-rated building systems, relies on precise engineering to ensure both transparency and fire integrity. One advanced manufacturing method involves creating a hollow interlayer between two glass panes, filled with a liquid fire-resistant resin that hardens under controlled conditions. This article details the step-by-step process, material considerations, and technical parameters involved in this specialized fabrication technique.

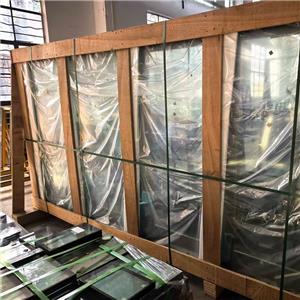

1. Material Preparation and Spacer Installation

The process begins with two sheets of tempered or laminated glass, typically 5–12 mm thick, cleaned and prepared for assembly. A fire-resistant spacer—often a silicone-based or ceramic-reinforced polymer strip—is positioned along the edges of one glass pane to create a uniform gap (usually 6–15 mm). The spacer contains desiccant particles to absorb residual moisture and is designed to withstand temperatures up to 400°C.

Key spacer properties:

Thermal stability: Maintains dimensional integrity during resin curing and fire exposure.

Adhesion compatibility: Bonds securely to both glass and resin.

Low thermal conductivity: Minimizes heat transfer across the interlayer.

The spacer layout leaves a small injection port (3–5 mm diameter) at one corner for resin filling.

2. Assembly and Formation of Hollow Interlayer

The second glass pane is carefully aligned and pressed onto the spacer-equipped pane, forming a sealed perimeter with the injection port as the sole opening. Vacuum pressure or mechanical clamps ensure uniform contact between the spacer and glass surfaces. The hollow cavity between the panes is then evacuated to remove air and moisture, a critical step to prevent bubbles and ensure resin adhesion.

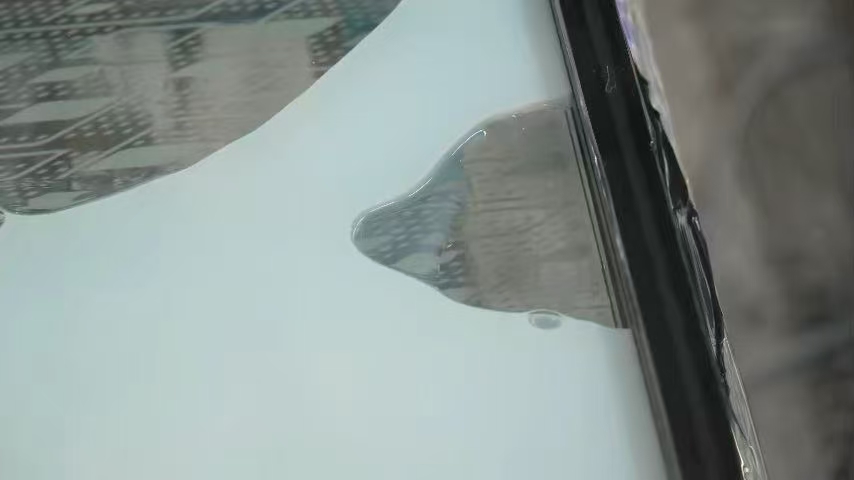

3. Injection of Liquid Fire-Resistant Resin

A proprietary liquid fire-resistant resin—composed of a thermosetting polymer (e.g., modified phenolic or silicone), flame-retardant additives (e.g., ammonium polyphosphate), and inorganic fillers (e.g., glass microspheres)—is injected into the cavity via the port. The resin formulation is engineered to balance viscosity, curing speed, and fire performance:

Typical resin properties:

Viscosity: 500–1,500 mPa·s (optimized for capillary flow without air entrapment).

Pot life: 30–60 minutes at 25°C.

Fire resistance: Expands to form a char layer at 150–250°C, providing up to 120 minutes of integrity (EN 1363-1 certified).

The injection process employs either gravity feeding or low-pressure pumps (0.1–0.3 MPa) to fill the cavity completely. Sensors monitor resin flow to detect blockages or incomplete filling.

4. Sealing and Initial Cure

Once the cavity is filled, the injection port is sealed using a high-temperature epoxy or laser welding. The assembly then undergoes room-temperature stabilization (12–24 hours) to allow partial polymerization of the resin, minimizing internal stress before oven curing.

5. High-Temperature Thermal Curing

The glass-resin assembly is transferred to a convection oven or autoclave for final curing. A controlled temperature ramp ensures gradual crosslinking:

Curing profile:

Ramp-up: 25°C → 80°C at 2°C/min (prevents rapid gas expansion).

Hold: 80–120°C for 2–4 hours (primary polymerization).

Post-cure: 140–160°C for 1 hour (enhances thermal stability).

During curing, the resin transitions from a liquid to a rigid, foam-like structure. The spacer and glass constrain expansion, ensuring dimensional accuracy.

6. Quality Control and Testing

Post-curing, the finished fire-resistant glass undergoes rigorous evaluation:

Visual inspection: Check for bubbles, discoloration, or delamination.

Ultrasonic testing: Verify resin homogeneity and bond integrity.

Fire testing: Expose samples to furnace conditions per EN 1364-1 to validate insulation and integrity ratings.

Weathering tests: Assess UV and humidity resistance per ASTM E2141.

7. Technical Advantages and Applications

This method offers several benefits over traditional wired glass or gel-filled alternatives:

Superior clarity: No optical distortion from spacers or filler particles.

Lightweight: Hollow structure reduces weight by 20–30% compared to solid fire-rated glass.

Customizable fire ratings: Adjust resin thickness and additives for 30–120 minute ratings.

Applications span high-rise façades, elevator lobbies, and industrial partitions where aesthetics and safety are paramount.

Conclusion

The hollow interlayer filling technique represents a sophisticated balance of materials science and precision engineering. By integrating optimized resin chemistry, controlled curing protocols, and rigorous quality assurance, manufacturers can produce fire-resistant glass that meets both architectural and life-safety demands. Future advancements may focus on UV-curable resins or nanotechnology additives to further enhance performance.

Core Keywords:

Fire-resistant spacer, liquid fire-resistant resin, thermal curing, EN 1363-1, hollow interlayer, resin injection.