Why Does Low-Quality Fire-Resistant Glass Turn Yellow?

Why Does Low-Quality Fire-Resistant Glass Turn Yellow? A Technical Analysis of Material Defects and Degradation Mechanisms

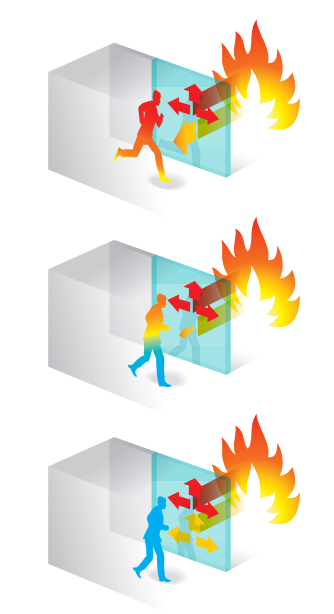

Fire-resistant glass (FRG) is a critical building material designed to maintain structural integrity and transparency under high temperatures, buying time for safe evacuation during fires. However, low-quality FRG often exhibits yellowing over time, compromising aesthetics and potentially signaling diminished fire resistance. This article examines the root causes of yellowing in substandard FRG through the lens of material science, exploring the chemical and physical mechanisms behind this phenomenon.

1. Structure and Function of Fire-Resistant Glass

FRG typically consists of multiple layers of inorganic glass (e.g., soda-lime silicate) bonded with an interlayer material, such as hydrated silicate gel, resin, or polymers. During a fire, the interlayer absorbs heat, releases bound water, and forms an insulating foam barrier to block flames (Figure 1). The efficacy of this process depends on the purity, stability, and manufacturing precision of the interlayer.

In low-quality FRG, cost-cutting measures—such as impure raw materials or poor production controls—trigger premature chemical or physical changes in the interlayer, leading to yellowing even before exposure to fire.

2. Five Key Causes of Yellowing in Low-Quality FRG

2.1 Oxidation Due to Impure Raw Materials

Substandard interlayers often contain sulfides (e.g., FeS₂), organic residues, or unrefined metal ions (e.g., iron, manganese). These impurities undergo oxidation under UV exposure or humid conditions:

Sulfide Oxidation: FeS₂ reacts with oxygen to form Fe³⁺ and sulfate ions (SO₄²⁻), producing a yellowish-brown tint.

Metal Ion Chromogenesis: Fe²⁺ oxidizes to Fe³⁺, forming [FeO₆]⁻ chromophores within the silicate matrix. These structures absorb blue light, resulting in yellow appearance.

Case Study: A batch of low-cost FRG in China yellowed within a year due to iron-contaminated silica gel.

2.2 Photo-Oxidative Degradation of Polymer Interlayers

Cheap FRG may use low-grade acrylic resins or polyvinyl butyral (PVB) without UV stabilizers. Under sunlight (280–400 nm UV), these polymers degrade via:

Norrish Type II Reactions: Carbonyl groups (C=O) absorb UV energy, triggering chain scission and releasing CO₂. This creates conjugated double bonds (e.g., alkenes or aromatics), which absorb blue light (450 nm) and cause yellowing.

Data: Accelerated aging tests show PVB interlayers without UV inhibitors exhibit a yellowing index (ΔYI) increase from 1.2 to 8.5 after 500 hours of xenon lamp exposure.

2.3 Thermal History and "Pre-Aging"

Poor temperature control during lamination (e.g., exceeding 150°C or localized overheating) induces thermal degradation:

Silica Gel Dehydration: Overheated hydrated sodium silicate (Na₂SiO₃·nH₂O) loses bound water, forming amorphous SiO₂ with Na⁺-related defect centers that absorb light.

Resin Over-Crosslinking: Epoxy resins subjected to excessive heat form dense aromatic structures, which strongly absorb visible light (380–500 nm).

Example: A production batch with faulty laminator temperature controls developed yellow clouding within three months of installation.

2.4 Additive Migration and Phase Separation

Low-cost FRG often incorporates incompatible flame retardants (e.g., decabromodiphenyl ether) or plasticizers (e.g., phthalates). These additives migrate to the surface over time, causing:

Surface Enrichment: Flame retardants aggregate at the glass-resin interface, forming micron-sized particles that scatter light (Mie scattering), creating a milky-yellow haze.

Hydrolysis Reactions: Phthalate plasticizers hydrolyze in humid environments to phthalic acid, which complexes with metal ions to form yellow compounds.

2.5 Environmental Contaminant Infiltration

Poor sealing in low-quality FRG allows acidic gases (SO₂, NOx) or volatile organic compounds (VOCs) to penetrate the interlayer:

Acid Etching: SO₂ reacts with moisture to form H₂SO₃, corroding the silicate network and releasing Fe³⁺ or Mn³⁺ ions. These ions react with sulfates to form yellow iron-sulfur compounds (e.g., FeSO₄).

Amine-Yellowing: Amine-based hardeners (e.g., ethylenediamine) in the interlayer react with CO₂ to form carbamates, which oxidize into quinone structures under light, yielding deep-yellow hues.

3. Mitigation Strategies and Quality Control

Raw Material Purification: Use ion exchange to remove Fe³⁺/Mn²⁺ from silica gel, ensuring sulfur content <50 ppm.

Stabilizer Additives: Incorporate 0.5–2% UV absorbers (e.g., benzotriazoles like Tinuvin 326) or hindered amine light stabilizers (HALS) into polymer interlayers.

Process Optimization: Strictly control lamination temperatures at 130±5°C and employ vacuum deaeration to prevent localized overheating.

Compatibility Design: Replace brominated flame retardants with phosphorus-based alternatives (e.g., DOPO) and enhance compatibility via graft modification.

4. Conclusion

Yellowing in low-quality FRG is a visible manifestation of material defects and environmental interactions, rooted in impurity-laden components, poor manufacturing, and inadequate aging resistance. By prioritizing material purity, stabilizer integration, and precision engineering, manufacturers can suppress yellowing and ensure FRG’s durability and safety.

Core Keywords:

Fire-resistant glass yellowing, photo-oxidative degradation, metal ion chromogenesis, thermal pre-aging, additive migration, environmental contamination