The Role of Glass Thickness in Fire Resistance Ratings

The Role of Glass Thickness in Fire Resistance Ratings

Thickness as a Component of System Integrity

A common misconception is that fire resistance is solely a function of glass thickness—the thicker the glass, the better the protection. While thickness is a critical factor, its role is more nuanced. In fire-resistant glass, thickness primarily contributes to the initial stability and integrity (E) of the assembly during the early stages of a fire. Thicker glass, especially tempered glass, has greater mechanical strength to withstand the thermal shock and pressure differences experienced in a fire, helping to prevent premature collapse. For example, the glass layers in PYRONANO's 25mm EI60 product provide the structural backbone. However, thickness alone cannot achieve a high fire rating. It is the synergy between the thickness of the glass panes and the performance of the intumescent interlayers that creates a truly effective barrier, as the interlayer's expansion is what ultimately provides insulation.

Glass Panes and Intumescent Interlayers

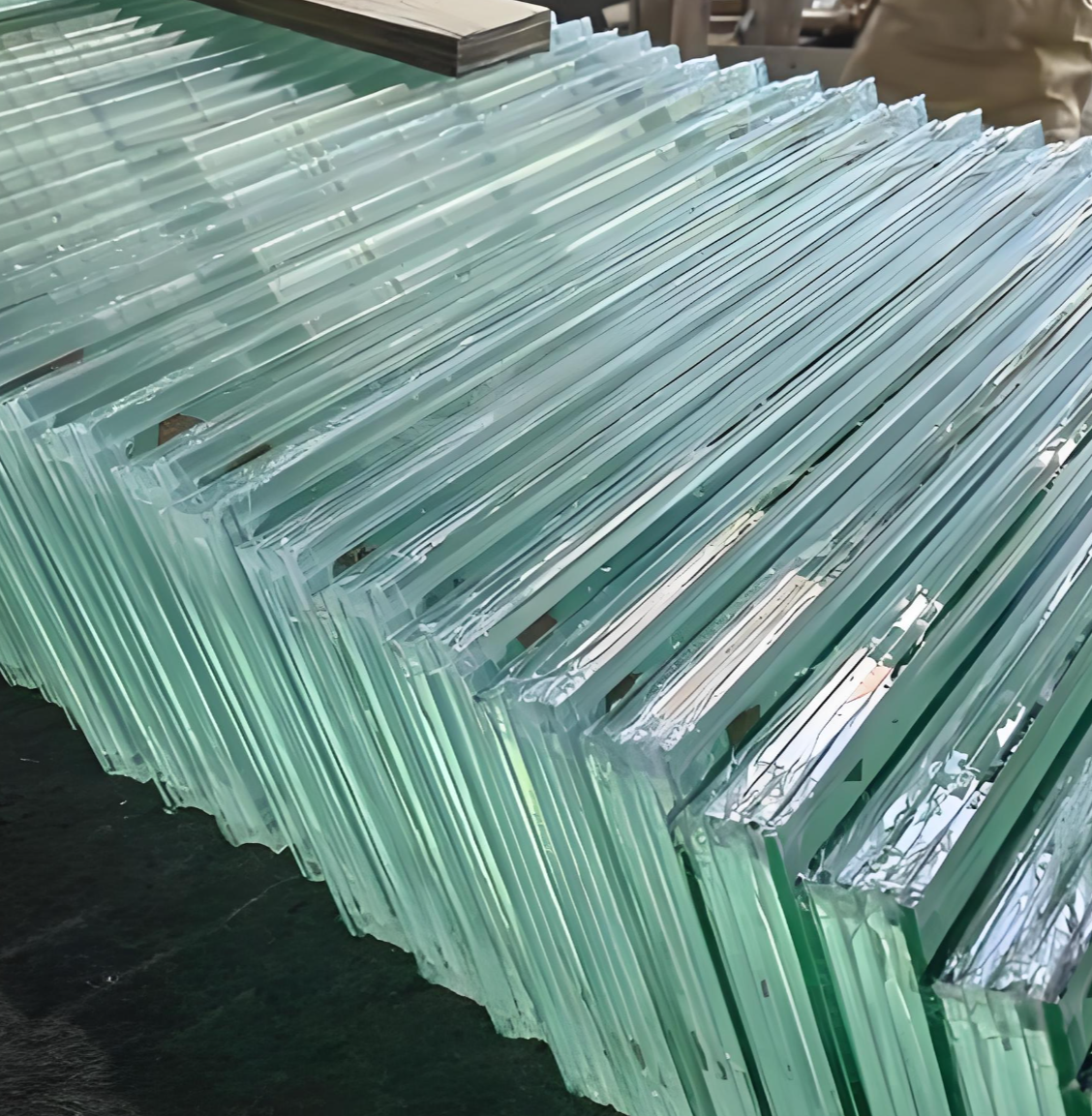

The core of modern fire-resistant glass technology lies in the multi-layer laminated structure, often denoted as "G + F + G" (Glass + Fire Interlayer + Glass). Here, thickness is strategically distributed. The fire resistance rating (e.g., EI 30, EI 60, EI 120) is directly influenced by the total number of glass layers, their individual thicknesses, and the number and thickness of the intumescent interlayers. A higher rating requires a more complex composition to delay heat transfer. For instance, PYRONANO's product for a 60-minute rating (EI60) may use a structure like 5G + 5F + 5G + 5F + 5G(totaling 25mm), whereas a 120-minute rating (EI120) would require an even more complex and thicker assembly with additional layers. The interlayers expand at high temperatures, forming a thick, opaque insulating foam. The thickness of the glass on either side contains this expansion and maintains the overall integrity of the assembly under intense heat.

Optimizing Thickness for Application-Specific Performance

Selecting the appropriate glass thickness is not about maximizing it indiscriminately but about optimizing it for the specific application, desired fire rating, and structural constraints. For a standard 60-minute fire door, a 25mm thick laminated glass unit might be ideal. However, for an oversized frameless glass wall requiring the same EI60 rating, the glass thickness and the supporting system must be engineered differently to handle larger spans and structural loads without heavy framing. Similarly, walkable fire-rated floors, like those from PYRONANO, utilize significant thickness and multiple layers of glass to combine fire resistance with load-bearing capacity. Therefore, manufacturers provide a range of thickness options for different ratings, and technical consultation is essential to choose the most efficient and cost-effective solution that meets both safety codes and architectural design requirements.

In summary, glass thickness is an indispensable, but not solitary, factor in determining fire resistance. It works in concert with the number of glass layers and the performance of intumescent interlayers within a certified system. The ultimate fire rating is a product of this sophisticated engineering balance. Understanding this relationship allows architects and specifiers to make informed decisions, relying on experts like PYRONANO to provide products where thickness is precisely calibrated to deliver guaranteed performance for each unique application.