Technical Challenges in Manufacturing Rigid Fire-Resistant Interlayer Glass

Technical Challenges in Manufacturing Rigid Fire-Resistant Interlayer Glass

Rigid fire-resistant interlayer glass is a critical building material designed to prevent flame and smoke spread while maintaining structural integrity during fires. Its production involves complex processes where precision and material science intersect. Despite its importance, manufacturers face significant technical challenges that impact quality, efficiency, and scalability. This article explores these challenges and the innovations addressing them.

1. Material Selection and Compatibility

Challenge:

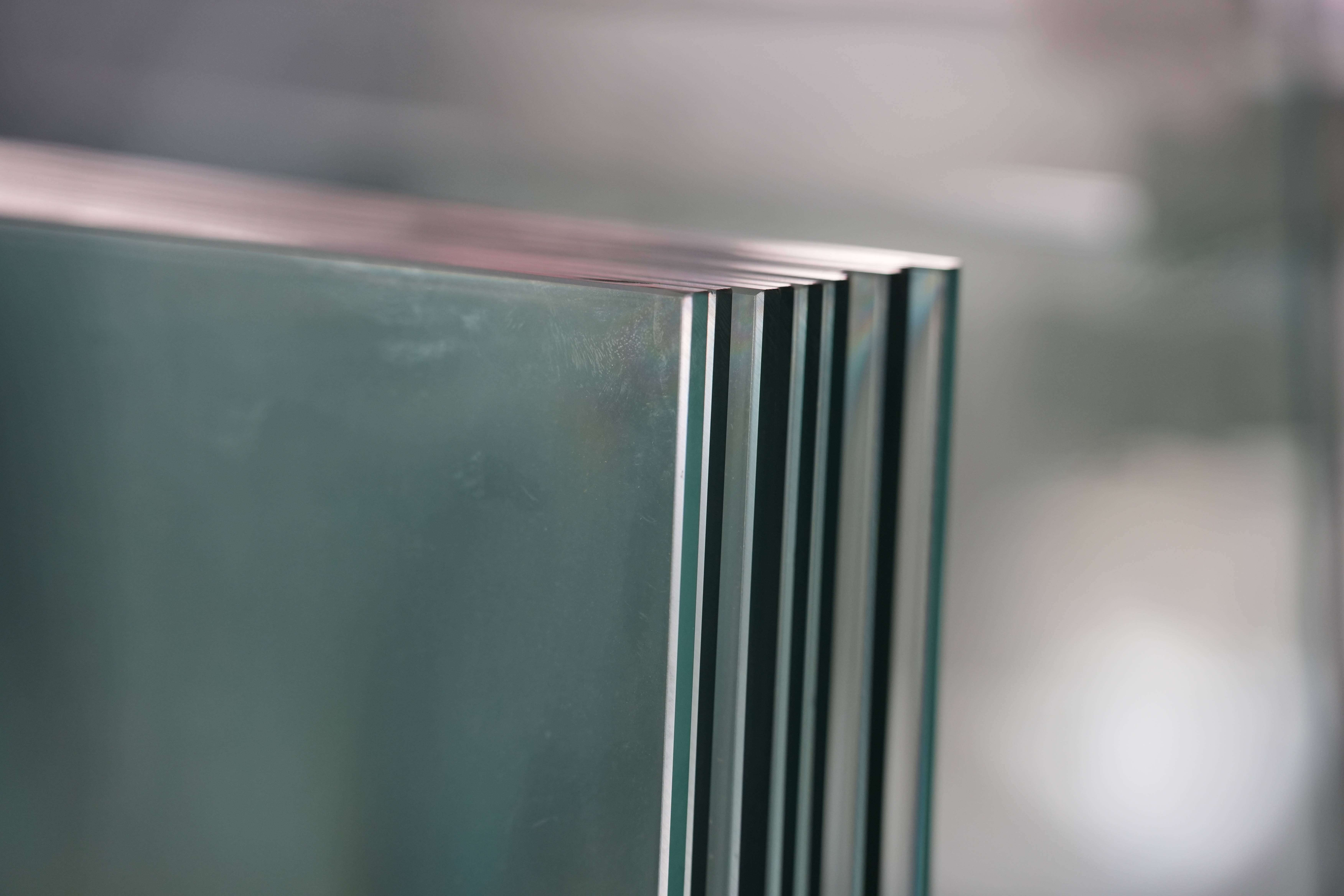

The core of rigid fire-resistant glass lies in its interlayer—typically a transparent, rigid gel or composite material (e.g., silica-based gels or alkali silicate solutions) sandwiched between glass panels. Achieving chemical stability and optical clarity while ensuring fire resistance is difficult. Incompatibilities between the glass (e.g., borosilicate, tempered soda-lime) and the interlayer can cause delamination, bubbling, or discoloration over time.

Critical Issues:

Thermal Expansion Mismatch: Glass and interlayer materials have different coefficients of thermal expansion. During temperature fluctuations, this mismatch induces stress, leading to cracks or debonding.

Moisture Sensitivity: Some interlayers (e.g., water-based alkali silicates) are hygroscopic. Moisture ingress during processing or use can cause cloudiness or reduce fire resistance.

Solutions:

Advanced Interlayer Formulations: Nanoparticle-enhanced gels (e.g., silica-zirconia composites) improve thermal stability and adhesion.

Surface Modification: Plasma treatment of glass surfaces before interlayer application enhances bonding and reduces delamination risks.

2. Precision in Interlayer Thickness and Uniformity

Challenge:

The fire resistance duration (e.g., 60, 90, or 120 minutes) directly depends on interlayer thickness and uniformity. Variations exceeding ±0.1 mm can compromise integrity during fires.

Critical Issues:

Flow Control During Lamination: Liquid interlayers must be evenly distributed without air pockets. In rigid glass assemblies, achieving this with viscous materials is highly challenging.

Curing Consistency: Inconsistent curing temperatures or times lead to uneven solidification, causing weak spots.

Solutions:

Automated Injection Systems: Precision nozzles and vacuum-assisted filling ensure uniform interlayer distribution.

Real-Time Monitoring: Laser scanners and sensors measure thickness during production, triggering automatic adjustments.

3. High-Temperature Processing and Thermal Stress

Challenge:

Rigid fire-resistant glass requires high-temperature processing (e.g., laminating at 80–120°C, curing up to 200°C). Excessive or uneven heat causes thermal shock, glass breakage, or interlayer degradation.

Critical Issues:

Glass Breakage During Cooling: Rapid cooling after thermal treatment induces stress fractures, especially in tempered glass.

Interlayer Degradation: Some gels lose transparency or form bubbles if overheated.

Solutions:

Gradual Cooling Protocols: Multi-stage cooling ovens reduce thermal shock. For example, cooling from 200°C to 80°C in controlled stages.

Low-Temperature Curing Agents: Modified interlayer chemistries (e.g., cerium-doped gels) allow curing at lower temperatures.

4. Mechanical Strength and Impact Resistance

Challenge:

Fire-resistant glass must dual-function: withstand fire and resist physical impact (e.g., human collision, debris). Balancing fire resistance with mechanical strength is difficult.

Critical Issues:

Brittleness of Interlayers: Rigid interlayers can be brittle, reducing overall impact resistance.

Edge Sealing Weakness: Improperly sealed edges are vulnerability points for impact and fire penetration.

Solutions:

Laminated Hybrid Designs: Combining rigid interlayers with flexible polycarbonate layers improves impact resistance.

Reinforced Edge Seals: Laser-welded metal frames or ceramic-based sealants enhance edge durability.

5. Quality Control and Certification Compliance

Challenge:

Rigid fire-resistant glass must meet strict international standards (e.g., EN 1363, ASTM E119). Testing is destructive and costly, and inconsistencies in production lead to high failure rates.

Critical Issues:

Defect Detection: Micro-bubbles, faint cracks, or uneven tints are hard to detect visually but cause certification failures.

Large-Panel Homogeneity: Maintaining uniformity in panels >2 m² is exceptionally challenging.

Solutions:

Automated Optical Inspection (AOI): AI-powered cameras scan for micro-defects and measure light distortion.

Small-Batch Testing: Continuous sampling during production reduces large-scale waste.

6. Scalability and Cost Efficiency

Challenge:

Many advanced processes (e.g., plasma treatment, nanoparticulate gels) are lab-effective but difficult to scale industrially while remaining cost-competitive.

Critical Issues:

High Energy Consumption: Prolonged high-temperature curing and cooling require significant energy.

Expensive Raw Materials: Specialty chemicals (e.g., zirconia, cerium salts) drive up costs.

Solutions:

Roll-to-Roll Processing: For smaller panels, continuous processing lines reduce energy use by 20–30%.

Recycled Glass Substrates: Using recycled borosilicate glass reduces material costs without compromising fire resistance.

Future Directions

Innovations aim to overcome these challenges:

Smart Interlayers: Embedding microsensors to monitor integrity in real-time.

Self-Healing Gels: Interlayers with reversible chemical bonds that repair microcracks.

AI-Optimized Production: Machine learning algorithms predict optimal curing parameters based on ambient conditions.

Conclusion

Manufacturing rigid fire-resistant interlayer glass requires overcoming multifaceted hurdles in materials, processing, and quality control. While challenges like thermal stress, scalability, and certification remain, advancements in nanotechnology, automation, and AI are driving the industry toward more reliable and efficient production. Collaboration between material scientists and manufacturing engineers will be key to achieving the next breakthrough in fire safety glass.

SEO Keywords:

Fire-resistant glass production challenges

Rigid fire-proof interlayer glass

Lamination defects fire-resistant glass

Borosilicate glass interlayer bonding

ASTM E119 compliance issues

Thermal stress in fire-resistant glass

Automated optical inspection glass manufacturing

Nanoparticle-enhanced fire-resistant gels

Fire-resistant glass certification testing

Scalability issues in glass laminating